End-to-End Service Management Software for Route Planning and First Class Customer Services

Digital Transformation in Customer Services – achieve more with less

The quality of Customer Service affects Customer Satisfaction and Loyalty.

A perfectly organised service at Customer site delivers a competitive advantage. Better problem diagnosis, staff selection, material supply and dynamic real-time scheduling increase speed and first-time-fix-rate.

Positive Customer Experience leads to new order opportunities, initiated and processed directly, on the spot, in person. Service digitisation enables cost savings and revenue enhancements – achieving more with less.

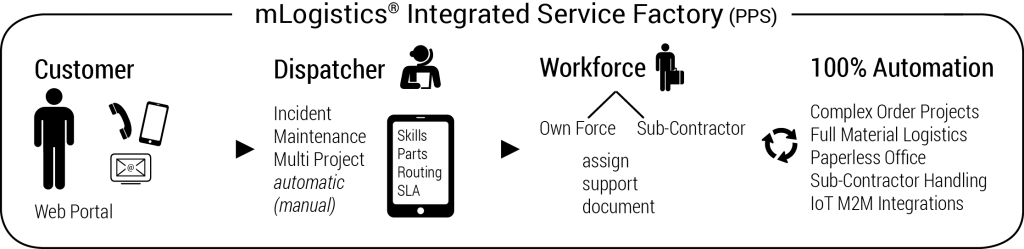

End-to-End Service Management in one Workflow: maximum efficiency – automated

Digital Transformation with Rapid ROI in job execution

Not just dispatching.

Our approach activates existing ERP systems through consistent real-time logistics..

The LogObject mission is the realisation of performance-critical job workflows in a holistic solution – real end-to-end.

Why LogObject?

Companies who benefit from mLogistics®

The mLogistcs® solution for Field Service Management can be used by all organisations who want to arrange their Mobile workforce efficiently with regular services and emergencies call outs by dispatching orders based on logistics.

This enables automated scheduling and scaling for an endless number of daily or parallel service orders. The application is equally valuable and efficient for large service organisations or businesses with a small workforce. Our smallest solution is used to organise businesses with about 20 staff.

What distinguishes mLogistics® from other solutions?

mLogistics® is a true end-to-end solution that continuously digitises all service processes and integrates them seamlessly with existing IT environments. Unlike out-of-the-box solutions, that only exchange data from existing systems, mLogistics® enables existing systems to be actively controlled by carrying out all logistic-based processes through mLogistics®.

As a result, logistics controlled automation for operational planning is feasible, and existing systems do not have to be expensively adapted. Another fundamental difference lies in software architecture that provides specific business-logic modules based on a core system. This leads to an Individual Standard that can be easily and quickly adjusted to specific Customer requirements.

How is seamless integration and automation achieved?

By sourcing all logistic processes, and use of mLogistics® Real-Time Adaptive Logistics Engine, a closed logistics cycle handles all specifications. From workforce planning to specific material requirements – mLogistics® establishes autonomous Service Operations Management. This eliminates the need for costly changes or adjustments to existing systems.

All that is required is an import or access to data that can be provided by standard interfaces. Typically, this data is available in existing ERP systems. If data is in silos – in various existing solutions or in sections – mLogistics® can map and import this data and prepare it for its own requirements. The basic structure of mLogistics® thus enables full integration without programmatic adjustments in existing systems

How can mLogistics® be introduced?

LogObject has years of experience in managing projects for large service organisations, especially in the performance-critical Communications Provider industries with their constantly changing product cycles and associated complex requirements of service teams and workflows.

This resulted in a successful best practice solution implemented by a plan that defines all processes that mLogistics® works out with the Client, using industry experienced project managers and a special development team.Thus, the implementation of a specific customised solution can be achieved in 4–6 months. Standardised solutions can be realised within a few weeks of starting depending on the availability of data.

What is the required investment?

LogObject achieves a superior ROI compared to SaaS solutions while at the same time offering a much simpler integration that enables a true end-to-end solution. Pricing is determined by usage, the number of user licences, a one-time expense of onboarding and integration of data, and a transparently calculated maintenance fee. Compared to SaaS solutions, leading to continuous high linear cost within a few months, a significantly lower TCO (Total Cost of Ownership) will be achieved at much lower costs of adaptation and implementation.

What is needed to start?

A clear idea of what perfect Field Service Management should achieve, and what the requirements are, become the basis of any decision on the right solution. Promises by other solution providers, that everything can be adapted, need to be thoroughly interrogated on the basis of the software architecture. Our Service Management Digitisation checklist contains requirements and specific tips for best decision-making.

Dynamic Process Management by mLogistics®

Current figures based on monthly average of daily on site service jobs for the existing universe of all LogObject’s users customer base and their total number of servicetechnicans available